Para compradores que compram racks de armazenamento de cozinha, durabilidade e resistência à corrosão não são negociáveis. Cozinhas comerciais, hotéis, e instalações de serviços de alimentação exigem soluções de armazenamento que resistam a ambientes agressivos – alta umidade, limpeza frequente, e exposição a substâncias ácidas ou salgadas. É aqui que os testes de névoa salina (também chamado de teste de névoa salina) torna-se uma etapa fundamental de garantia de qualidade.

Neste artigo, exploramos como os testes de névoa salina se alinham aos padrões da indústria, como ASTM B117 e garante o seu cestas de armazenamento de arame de cozinha atender às expectativas de desempenho de longo prazo.

O que é teste de névoa salina?

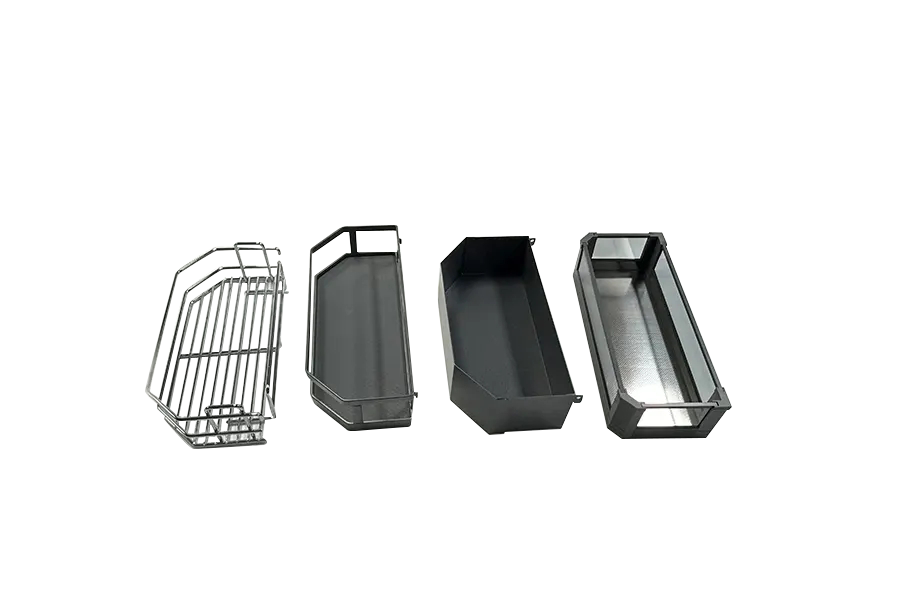

O teste de névoa salina simula testes de corrosão acelerados para avaliar como os componentes de armazenamento da cozinha, como cestas de arame de aço inoxidável ou prateleiras de metal galvanizado– aguentar ao longo do tempo. Durante o teste, as amostras são expostas a uma névoa salina controlada (5% Solução de NaCl) em uma câmara selada, replicando anos de estresse ambiental em apenas alguns dias.

Principais métricas medidas:

- Tempo para corrosão inicial (ferrugem branca ou ferrugem vermelha)

- Durabilidade do revestimento para revestido a pó cestas de cozinha

- Degradação de materiais sob exposição prolongada

Por que fornecedor Deve priorizar o spray de sal testado Soluções de armazenamento de cozinha

1. Conformidade com Padrões Globais

Fabricantes respeitáveis aderem à ASTM B117 ou ISO 9227 protocolos de teste. Os produtos que passam nesses testes garantem a conformidade com regulamentos da indústria alimentar e certificações de cozinha, reduzindo riscos de responsabilidade para compradores.

2. Vida útil prolongada do produto

Cestos de armazenamento de cozinha suportam o desgaste diário causado pela umidade, graxa, e agentes de limpeza. O teste de névoa salina identifica pontos fracos em malha de aço inoxidável ou revestimentos galvanizados, garantindo que seu pedido em grandes quantidades resista 500+ horas de resistência à névoa salina (ou superior para aplicações de nível marítimo).

3. Eficiência de custos em compras em massa

Soluções de armazenamento de cozinha à prova de ferrugem reduzir a frequência de substituição, reduzindo os custos a longo prazo para fornecedores de hospitalidade e distribuidores de equipamentos para foodservice.

4. Proteção da reputação da marca

Soluções de armazenamento propensas a falhas levam a reclamações de clientes. Cestos resistentes à corrosão certificados aumentar a confiabilidade da sua marca como fornecedora de sistemas de organização de cozinha.

Interpretação dos resultados do teste de névoa salina para prateleiras de armazenamento de cozinha

Ao avaliar fornecedores, solicitar relatórios de teste especificando:

- Duração do teste: 24h às 1.000h (horas mais altas = melhor resistência à água salgada Resistência à corrosão)

- Tipo de revestimento: Galvanizado, galvanizado, ou aço inoxidável 304/316

- Classificação de desempenho: Aprovação/reprovação com base na prevenção de ferrugem visível ou pós-teste de formação de bolhas no revestimento

Exemplo: Um teste de névoa salina de 720 horas para 316 cestas de arame de aço inoxidável devem apresentar zero ferrugem vermelha, garantindo a adequação para garantir a adequação para cozinhas costeiras ou armazenamento de alimentos com alta umidade.

Escolhendo um fornecedor: 3 Perguntas críticas para compradores

- Faça o seu cestas de armazenamento de metal passar por testes de névoa salina em nível de lote?

- Quais classes de aço inoxidável (Por exemplo, 304 contra 316) você recomenda para racks próprios para lava-louças ou ambientes de cozinha industrial?

- Você pode fornecer certificados de teste em conformidade com ASTM/ISO para superfícies de contato com alimentos??

Conclusão: Invista em Testado, Soluções confiáveis de armazenamento de metal

O teste de névoa salina para utensílios de cozinha não é apenas uma caixa de seleção – é uma proteção contra corrosão prematura e interrupções na cadeia de fornecimento. Faça parceria com fabricantes que priorizam testes de controle de qualidade, garantindo que suas cestas de arame de nível comercial ofereçam resistência à ferrugem incomparável e ROI de longo prazo.