Пытаемся удовлетворить растущий спрос на решения для хранения в шкафах премиум-класса.? Бене предлагает высококачественную корпусную фурнитуру, которая не только улучшает эстетику кухни и ванной комнаты, но и упрощает повседневную работу по дому.. Наша непоколебимая приверженность качеству и инновациям выделяет нас как ведущего поставщика Китая.. Узнайте, как Bene может улучшить вашу линейку продуктов.

Производственный процесс

Производство оборудования для шкафного хранения имеет решающее значение для улучшения организации., функциональность, и безопасность на кухне и дома. Высококачественные компоненты обеспечивают долговечность, соответствовать санитарным и экологическим стандартам, и улучшить эстетику. Пожалуйста, взгляните на производственный процесс в Бене..

1. Выбор материала

Первый этап точного контроля включает строгий отбор сырья..

Bene гарантирует качество, выбирая высококачественные материалы, такие как 6063 алюминий и железо Q159.

Мы также используем спектральный анализ для проверки состава материала., обеспечение соответствия продукции стандартам.

2. Проектирование и прототипирование

- Создание эскизов и 3D-моделирование

На основании требований, дизайнеры рисуют эскизы и используют программное обеспечение САПР для создания подробных чертежей или 3D-моделей.

Это не только помогает визуализировать продукт, но и позволяет нам выявить недостатки дизайна на ранней стадии..

- Создание и тестирование прототипа

Мы используем такие технологии, как 3D-печать или обработка на станке с ЧПУ, для создания прототипов продукции, проведения функциональных испытаний и оценки внешнего вида.. В котором, продукт оптимизируется перед массовым производством.

3. Производственный процесс

Сначала, мы разрезаем сырье, такое как металлические листы и стержни, на точные формы с помощью лазерной резки., гидроабразивная резка, и распиловка. Этот шаг жизненно важен: если вы сделаете его правильно, все последующие действия будут идеально сочетаться друг с другом..

Следующий, мы используем штамповочные машины для придания этим вырезанным материалам детальных конструкций.. Стемпинг – это не просто создание классных форм; это также повышает прочность и стабильность деталей..

Затем идет сварка. Мы используем МИГ, ТИГ, и точечная сварка для соединения деталей в прочные сборки.. То, насколько хорошо мы свариваем, имеет решающее значение — прочность, безопасные сварные швы означают, что конечный продукт прочный и надежный.

Окончательно, мы сверлим точные отверстия и обрабатываем детали по точным спецификациям. Этот шаг гарантирует, что каждый компонент подходит и работает правильно., завершение производственного процесса.

4. Обработка поверхности

- Очистка

Чистая поверхность необходима для адгезии последующих покрытий..

Использование таких методов, как химическая очистка., и пескоструйная обработка, удаляем грязь и загрязнения с поверхностей материала.

- Полировка

С помощью абразивов и полировальных машин., сглаживаем и выравниваем поверхности деталей, улучшение их внешнего вида. Полировка не только делает изделие более эстетичным, но и повышает его коррозионную стойкость..

5. Напыление и гальваника

Это также называется Поверхностная обработка в хорошем. Процесс включает напыление и гальваническое покрытие для обеспечения качества продукта..

- Распыление

Этот процесс включает использование полимерных материалов, таких как полиэфирные и эпоксидные смолы, для создания порошка., который затем распыляется на поверхности оборудования.. Результат – гладкая, прочное покрытие, устойчивое к износу, коррозия, и высокая температура..

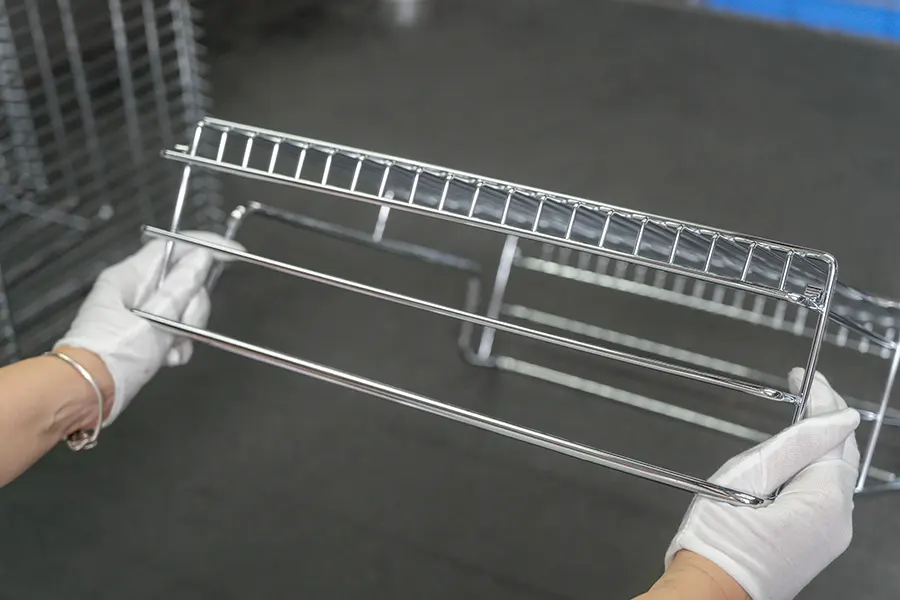

- Гальванизация

Бене использует гальваническое покрытие для управления Cr3 при обработке поверхности.

Этот процесс включает погружение металлических деталей в раствор с ионами Cr3 и подачу электрического тока.

Этот метод создает равномерный слой хрома на поверхности., обеспечивает надежную защиту от ржавчины, и носить, и улучшение как электропроводности, так и теплопроводности.

Контроль качества

Контроль качества жизненно важно для обеспечения безопасности продукции, надежный, и соответствовать высоким стандартам. Это помогает предотвратить дефекты, поддерживает последовательность, и укрепляет доверие клиентов, поставляя надежную и высококачественную продукцию. Вот обзор процесса в Бене:

Контроль сырья

Качество видно в мельчайших деталях. Мы начинаем контролировать точность нашей продукции от источника сырье и тестирование сырья.

Тестирование материалов:

- Спектрометрическое тестирование: Подтвердите тип сырья и содержание никеля.

- Тестирование солевого распыления: Статус антикоррозионной способности

Контроль технического обслуживания машины

Бене уделяет особое внимание ежедневной чистке и обслуживанию машин.

Во время производства, мы регулируем производительность машины по мере необходимости.

Мы контролируем температуру заливки масла и вакуумной вытяжки, чтобы предотвратить влияние пузырьков воздуха на работу машины и допуск по размеру продукта..

Проверка производственного процесса

Инспекторы качества играют решающую роль во время производства, обеспечение соответствия продукции стандартам.

Они проверяют такие проблемы, как пропажа, излишний, или неправильные сварные швы, которые могут повлиять на качество и безопасность продукции.

Раннее обнаружение и решение этих проблем помогают предотвратить дефекты и поддерживать высокое качество продукции..

Проверка готовой продукции

После производства, мы проверяем и тестируем поверхность готового изделия.

Проверяем герметичность сварных соединений и проводим экологические испытания.

Мы используем экологически чистое покрытие и избегаем материалов с высоким содержанием свинца, чтобы соответствовать экологическим стандартам..

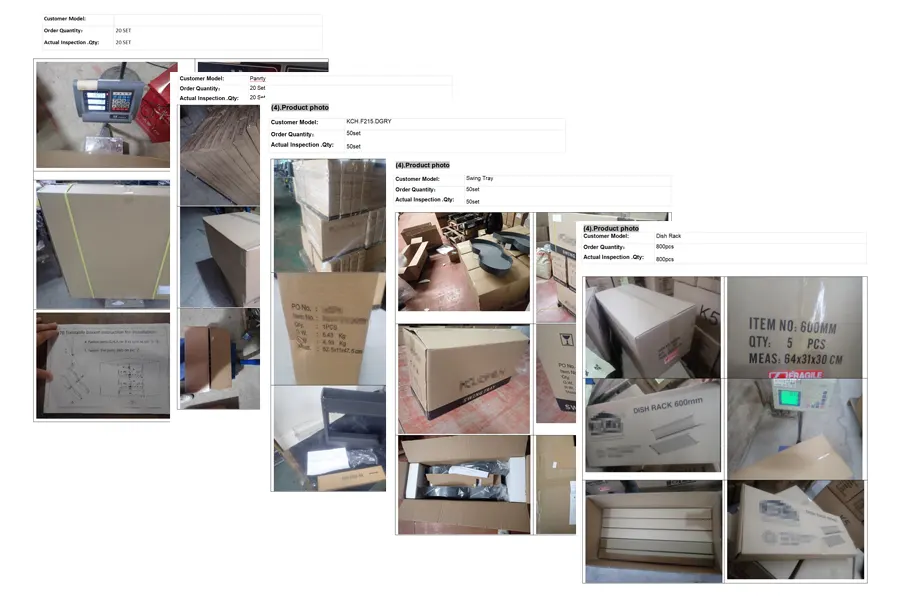

Завершение проверки

Бене следует строгому 135 система контроля качества на протяжении всего производства. Наша продукция подлежит строгой системе контроля качества AQL., с тремя выборочными проверками:

1. Выборочная проверка ручной формы

2. Выборочная проверка перед массовым производством

3. Выборочная проверка после завершения производства

Специализированный и опытный персонал контроля качества управляет всем процессом контроля качества.. Мы также проводим предотгрузочную проверку, чтобы обеспечить удовлетворенность клиентов., выдача отчета по итогам проверки. Каждый год, мы генерируем более 10,000 отчеты о качестве.

Обзор Бене

В Бене, Мы стремимся предоставлять первоклассное оборудование для хранения в шкафах, которое упрощает повседневную жизнь домохозяек.. Наша приверженность качеству очевидна на каждом этапе нашего процесса., от тщательного тестирования сырья и точного обслуживания оборудования до тщательных проверок до и после производства. Мы используем передовые технологии, такие как порошковое покрытие пищевого качества и специализированную обработку, чтобы обеспечить долговечность., безопасность, и экологичность.

С более чем 17 многолетний опыт, современный завод, и ISO 9000 сертификация, Bene выделяется своим качеством и надежностью.. Обращайтесь к нам за оборудованием, которое соответствует самым высоким стандартам и обеспечивает исключительную производительность.

Связаться с Бене сегодня, чтобы узнать, как наше оборудование может улучшить ваши предложения.