In Bene, clients can easily choose from a range of options such as pull down closet rod,rotating shoe rack, pants hangers and more. They can how Bene customized closet hardware solutions bring everything within reach.

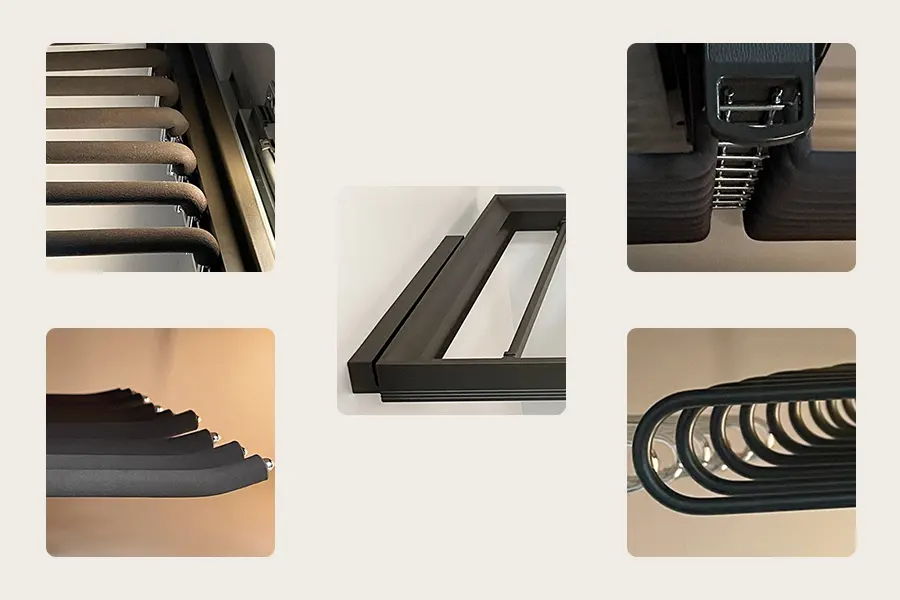

Pull Down Closet Rod

The double-buffered structure guarantees that there is no bounce when using.

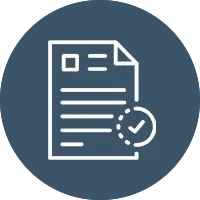

Pants Hangers

Designed to be multifunctional, space-saving to keep wardrobe tidy.

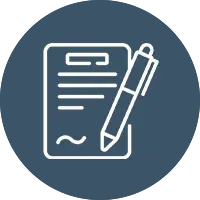

Rotating Shoe Rack

High-quality resistance oils were used to control the tolerance +0.01ml to ensure the shoe rack could be rotated smoothly.

There are three basic categories of wardrobe storage hardware, and they are all customizable according to different sorts of wardrobes. View more for more details for your cabinet business.

Convert your customers’ wardrobe into more practical and usable space with closet storage hardware from Bene.

Bene provides more sizes of storage hardware to suit your cabinet business than markets, which can utilize the full space of the cabinet and bring people a better living experience.

With high-quality products and MPG systems during the shipping, Bene brings our customers an effortless cooperation.

A strong and experienced R&D team is the best foundation for you to lead the cabinetry-making industry.

Customize your cabinet&closet organizer hardware with our wide range of options to drive your brand.

Bene offers a wide array of size options to accommodate various cabinet sizes.

Pull down closet rod:450/600/830/1150mm

Rotating show rack:360*700mm

Pants hanger:450*215*81mm

Before production, Bene has our expert R&D team available for you to confirm the function of the products, and we are committed to bringing your idea to life.

We strictly control the raw material of 201/304 stainless steel. and also provides a variety of basket styles for your consideration.

We will apply different surface treatment technologies to our products to meet your needs for color.

In order to better serve our customers, we will also provide you with customized packaging services. We will thoroughly regulate everything, including the substance used for the wrapping paper and the drop test.

During the customization process, Bene communicates with our customers until their demands are met. We strictly control every step of the production to ensure high-quality products.

All our customers deserve a sincere treat. We will take all your demands into serious consideration.

Before proofing, we have our R&D team confirm the function demands from our customer.

At this stage, we will cut out samples according to your demands with a laser machine.

We have our design team confirm the size of products in the drawing.

After confirming the function and size, we sign the contract.

The customer can make a precision adjustment after the prenatal sample is produced.

Our dedicated quality inspectors will finish testing during mid-term production.

We maintain the machine well and have strict QC inspections to control the high precision of the product.

Our experienced QC staff guarantees a low number of defective products in the final inspection.