Quality Control

Our quality control system ensures top-quality products through a 135-point inspection process, AQL system, and strict checks on materials and finished goods. We use advanced equipment and tools to guarantee consistency and reliability,and to ensure that our customers receive top-quality products.

Accuracy Pre-control

- The first stage of precision control is mainly reflected in our strict testing of raw materials. We confirm the content and class of material composition by sending the spectral analysis of potion in order to make the produced products meet the standard requirements.

- Bene will also control the quality of products through material selection, we choose hardness 6063 aluminum material and iron Q159 material.

Machine Maintain Control

- Bene pays attention to the daily cleaning and maintenance of the machine. During the production process, we also adjust the performance of the machine in time.

- We pay attention to controlling the temperature difference of oil filling and vacuum exhaust to avoid air bubbles affecting the machine operation is not smooth, so as to control the product size tolerance.

Production Process Inspection

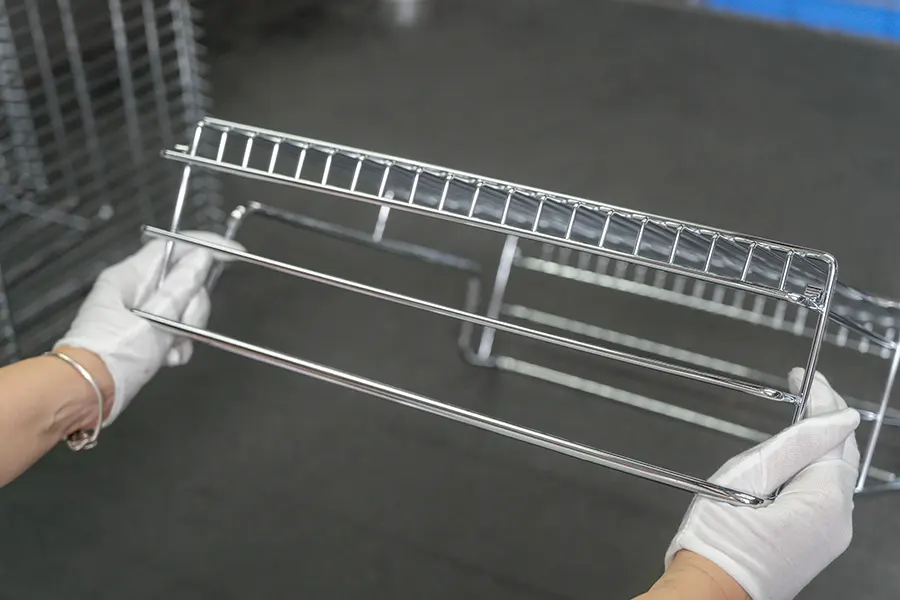

In the production process, quality inspectors play a crucial role in ensuring that the products meet the required standards. They conduct inspections to detect any potential issues such as missing, excessive, or incorrect welds, which could compromise the quality and safety of the products. By identifying and addressing these issues early on, they help to prevent defects and ensure that the products are of the highest quality possible.

Finished Product Inspection

After the finished product is produced, the surface of the product is inspected and tested. Mainly, we check whether the welding pair interface is tight and the environmental protection testing of the product surface. We use environmental protection plating, avoid using things with high lead content, to achieve environmental protection requirements.

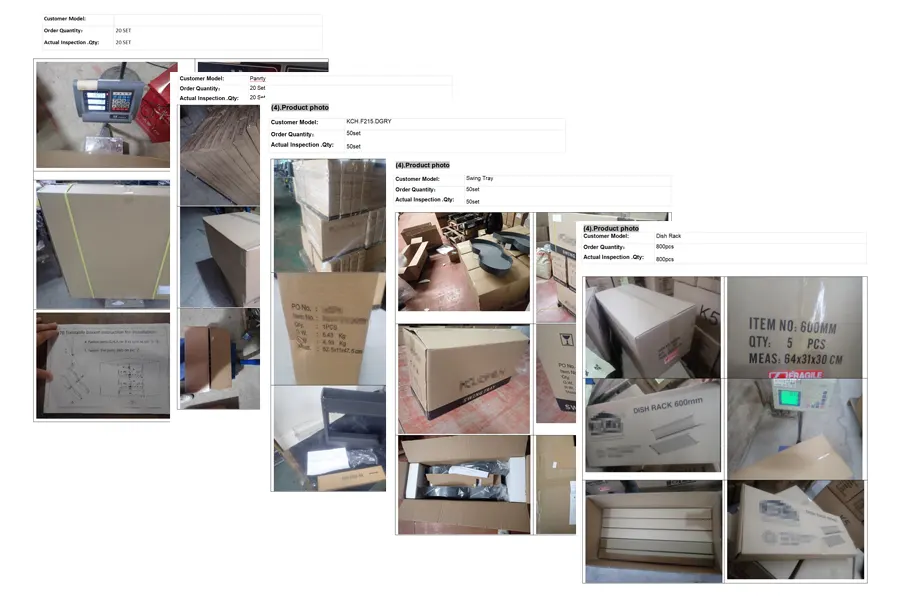

End Inspection

Bene has its own 135 quality control system, which is always present during the production process. All Bene products follow a strict AQL quality control system. There are three spot checks during the whole customization process:

- the first one is the hand mold spot check;

- the second one is the spot check before mass production;

- the last one is the spot check when the finished products are produced.

The whole quality control process is handled by specialized and experienced QC staff throughout. In addition, we will also carry out a pre-shipment inspection to ensure that customers get satisfactory and assured products. A report will also be issued to the customer during the end inspection. We have issued 1W+ reports every year.