Bene’s pull down basket uses an upgraded mechanical arm design to avoid the noise problems caused by the traditional chain structure while increasing the ease of adjusting the pulling mode and obtaining a patent. Better serve our cabinetry-making customer base with high-quality products.

Both the materials and the design require Bene’s effort. The chrome-plated iron material of the products is anti-corrosion and anti-rust. The heavy-gauge wire structure provides extra durability and elegance. Browse more high-end pull down baskets below for your cabinet business.

Bene focuses on the overall quality of our products, as detailed as adjusting slide tolerances and bearing points, etc. We are committed to providing one-stop solutions to further customers’ cabinetry careers.

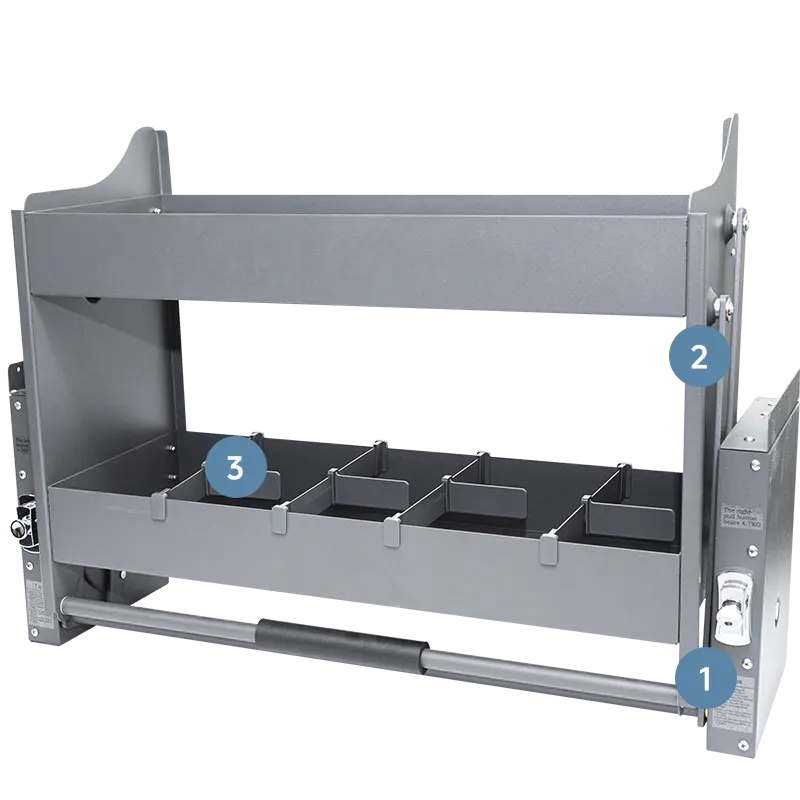

The strong load-bearing frame ensures it is not easy to deform and has a strong bearing capacity of 25kg for each basket.

The hydraulic buffer system guarantees stable lifting without jamming, rapid drop, and shaking, as well as complete silence.

Press the button to rotate the gear to adjust three kinds of tension.

Soft-close and silent damping designs and adjustable caging device to prevent it from bouncing.

We mean what we mean. Every business has specific needs, which is why all our products are custom-made to any size, function, material,color and package . So even if you don’t see what you want, just let us know, and we will figure out a way!

During the customization process, Bene communicates with our customers until their demands are met. We strictly control every step of the production to ensure high-quality products.

All our customers deserve a sincere treat. We will take all your demands into serious consideration.

Before proofing, we have our R&D team confirm the function demands from our customer.

At this stage, we will cut out samples according to your demands with a laser machine.

We have our design team confirm the size of products in the drawing.

After confirming the function and size, we sign the contract.

The customer can make a precision adjustment after the prenatal sample is produced.

Our dedicated quality inspectors will finish testing during mid-term production.

We maintain the machine well and have strict QC inspections to control the high precision of the product.

Our experienced QC staff guarantees a low number of defective products in the final inspection.